Modular Function Deployment®

Apply Modular Function Deployment (MFD®) to create product architectures that meet customer needs, strategic targets and functional requirements.

MFD enables you to balance stakeholder perspectives and create a product architecture that reduces complexity and accelerates value creation. With MFD and the accompanying information model, end customers can configure their own solutions and you can build a competitive advantage.

And that’s when the fun really starts.

How to Balance Stakeholder Perspectives?

The objective of Modular Function Deployment® (MFD) is to create a modular system that integrates and balances stakeholder perspectives. With this architecture in place, you can enable the mass customization of products and services, reduce complexity and accelerate value creation.

With MFD, stakeholders are represented by one of the following voices:

-

Voice of Customer

-

Voice of Engineering

-

Voice of Business

-

Voice of Modularity.

Voice of Customer represents the marketing, sales, and service functions of the organization as they strive to satisfy customer needs.

Voice of Engineering represents the engineering and design functions as they strive to develop and choose technical solutions that are combined into products and services.

Voice of Business represents company strategy, operations, and finance. These functions work together to guide decision-making and make and supply products as specified in the product development process.

The power of the modular product architecture itself is integrated as an additional voice, the Voice of Modularity.

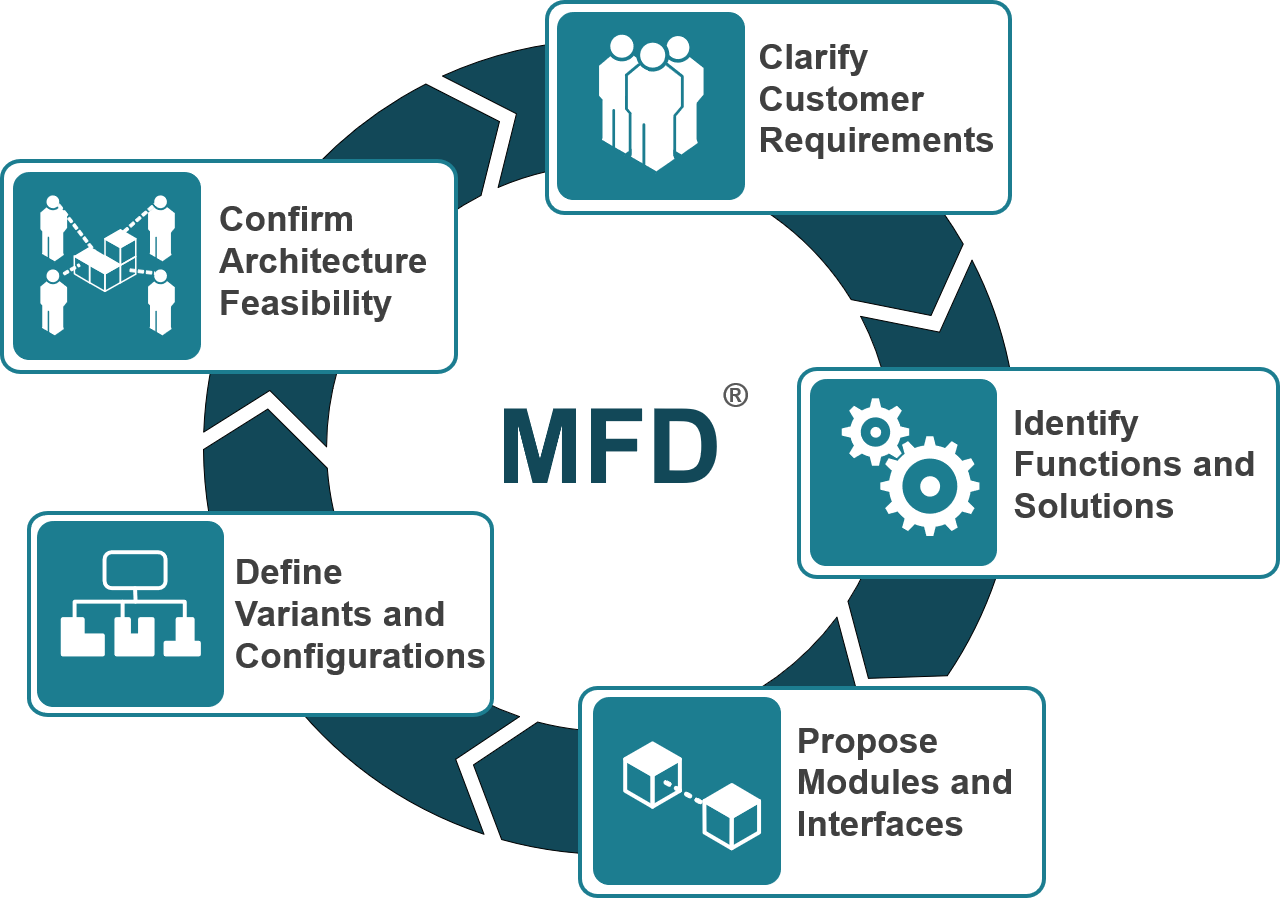

MFD has five steps to discover, capture, quantify and document the unique perspective of each stakeholder's voice. Activities are supported by established methods and tools. The method is iterative and progresses through each step so the modular product architecture can be built and refined. Analysis and a clear governance model balances all stakeholder perspectives to connect your customers, products, services and people.

PALMA®

Modular Function Deployment® (MFD) is a method to create product architectures. Combined with PALMA® Strategic Software you can link the architecture to a universal information model that enables the mass customization of products and services and connects your organization. PALMA is the world-class solution for product management.

Standing for Product Assortment Lifecycle Management, PALMA is cloud-based strategic software for how to create, document and govern modular product architectures. With this unique structured approach and strategic software you can design, document and configure products. You can also connect enterprise systems and secure business goals.

Built on an in-memory database platform, PALMA is faster and more capable than anything else on the market, so you can create configuration rules without coding, govern product architecture life cycles and create a business advantage.