When discussing modularization, key terms like "mass customization" and "configurator" come up frequently. These concepts are integral to achieving meaningful results from modularization efforts and demonstrate its tangible benefits. In this article, we’ll focus on configurators — one of the most impactful tools resulting from successful modularization.

A Brief History of Configurators in Manufacturing

To begin, let’s examine the introduction and application of configurators in the manufacturing industry. Configurators emerged as essential tools to help manufacturers meet the growing demands for product diversification and customization. The history of configurators can be traced back to the computer industry in the 1970s, long before the era of email or internet connectivity. Even then, configurators were used to streamline the process of building complex computer systems by enabling manufacturers to meet customer specifications with precision.

For instance, clients could input specific performance requirements, such as desired processing speed or printing capabilities. The configurator would then automatically generate a complete configuration, including the necessary CPU, memory, bus, disk, and even cabling requirements. Once the sales team confirmed the order, the configurator issued a unique serial number and a clear delivery timeline. This ensured that each custom system was assembled precisely to specification, from hardware configuration to operating system installation, enabling a seamless and reliable setup for the customer. This systematic approach became essential across various platforms, including UNIX and Windows-based servers, proving configurators’ versatility and value across computing environments.

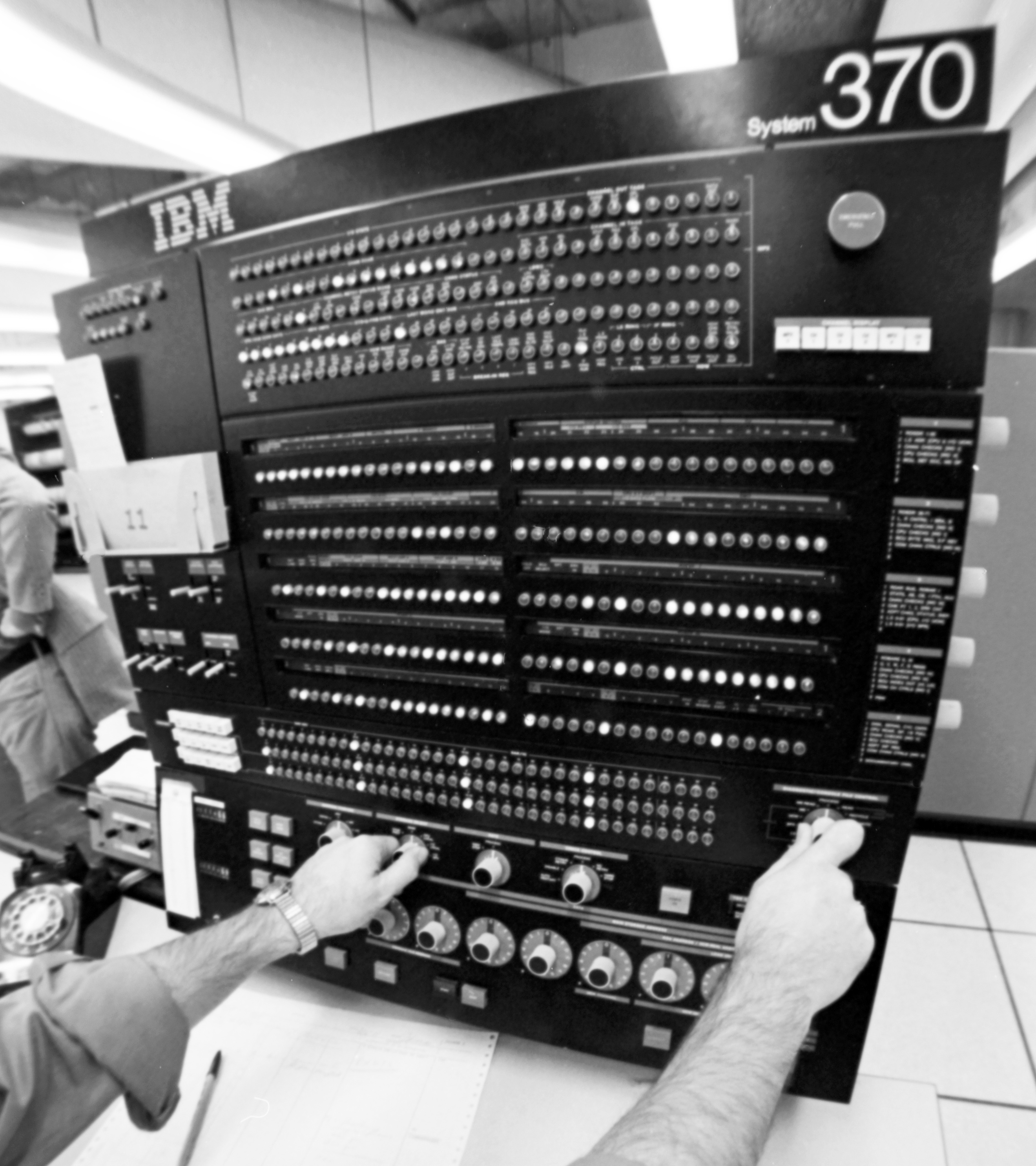

IBM System/370, the most successful computer system in history

The Evolution of Configurators: From Hierarchy to User-Centric Design

This early approach of using fixed logic to assign modules from a predefined product hierarchy represents the "first generation" of configurators. These configurators relied on structured, hierarchical frameworks, generating configurations based on preset rules — a foundational method that paved the way for today’s more adaptive systems.

Following this initial phase, configurators evolved to focus more closely on user-defined requirements, enabling product selection based on the specific needs and preferences of the end user. For large-scale products, such as gas turbines and auxiliary systems used in LNG power plants, configurators became indispensable. These industrial gas turbines can consist of up to 50,000 individual components, each chosen based on precise specifications. With products of this complexity, where configurations are custom-built and can cost billions, traditional manual selection is insufficient; sophisticated logic within configurators is essential to streamline the selection of modules and components.

European manufacturers of gas turbines were among the first to implement configurators aimed at achieving a stable and consistent business process by reducing reliance on manual configuration. This generation of configurators no longer relied solely on predefined specifications, as in the early models. Instead, they operated from the perspective of the end user, such as power plant operators, who require configurations based on specific performance and environmental factors — maximum output, continuous operational hours, altitude, temperature range, air pressure variations, noise restrictions, fuel types, and maintenance schedules. This shift towards user-centric configurators marked a significant development, enabling customized configurations that directly align with complex operational demands.

Gas Turbine Business that Succeeded with the Introduction of Configurator

Before configurators, highly skilled engineers had to manually calculate and specify each component to meet customer requirements. This process involved extensive coordination across departments and often resulted in lengthy documentation — up to 500 pages covering specifications, pricing, and delivery timelines. Completing these specifications could take up to eight weeks, creating delays and requiring significant manpower.

The introduction of configurators, however, revolutionized this process. By inputting key parameters directly into the configurator, even on mobile devices like an iPad, users can now generate accurate specifications and pricing within minutes — without needing continuous support from an engineer. This ability to deliver instant specifications is particularly valuable for large-scale projects, where rapid estimation enables better planning and profitability assessments. Additionally, configurators support competitive positioning by allowing companies to quickly generate bid-ready specifications and pricing, which can be crucial in time-sensitive budget approvals and procurement cycles. This approach — configuring products based on detailed user scenarios — marks the evolution of the "second-generation configurator," a system designed to align closely with complex, project-specific demands and improve the speed and precision of the entire specification process.

An advanced configurator should prioritize specifications based on user preferences rather than following a rigid, top-to-bottom hierarchical selection. For example, consider the process of purchasing a car. When I bought a vehicle around 2000, the salesperson guided me through the decisions on model, engine displacement, and trim level. However, when it came to selecting the color — a high priority for me — the salesperson informed me that my chosen color was not available for that particular model and grade combination, reverting the configuration to a default white option.

This experience highlights the importance of flexible configurators that adapt to user priorities. In scenarios like vehicle purchasing, customers may have specific preferences for aspects such as model, capacity, or color. However, with rigid configurators that lack the flexibility to accommodate user priorities, customers often encounter limitations. Advanced configurators, by contrast, streamline the process by adjusting configurations to respect individual preferences, improving the overall experience and ensuring that critical specifications align with user expectations.

How Configurators Drive Efficiency and Flexibility in Manufacturing

Configurators play a pivotal role in the manufacturing industry by enabling product customization and supporting efficient production processes. Below is a summary of the key areas where configurators bring value to manufacturing:

-

Product Variant Management

Managing product variants is essential in manufacturing, where customers often demand multiple product options. Configurators streamline variant management by easily handling diverse configurations and generating precise, error-free specifications across all variants. This capability reduces manual intervention and ensures consistency in product offerings. -

Enhancing Production Process Efficiency

- Automated Design and Estimation: Configurators accelerate the quoting and estimation process by automatically generating detailed design data based on selected configurations. This automation speeds up customer response times, improves accuracy, and reduces errors in quoting. Although providing an exact delivery date can still be challenging with standard configurators, automation helps set realistic timelines.

- Generating Production Instructions: Based on selected specifications, configurators produce precise manufacturing instructions for production teams. This reduces manual error, minimizes ambiguity, and enhances efficiency on the factory floor, supporting a streamlined transition from design to production.

-

Cost Reduction and Inventory Optimization

- Inventory Optimization: Configurators optimize inventory levels by calculating the exact materials needed for each configuration, reducing overstock and lowering holding costs. This targeted approach leads to substantial cost savings by ensuring that only essential parts are produced.

- Shorter Lead Times: Standardizing component configurations helps streamline processes from engineering to manufacturing to delivery. This efficiency reduces lead times, which ultimately enhances customer satisfaction by meeting delivery expectations.

-

Agility and Market Responsiveness

- Capturing Inbound Markets: Embedding configurators directly into a company’s website can attract new customers who may not be traditional clients, as well as users with unique use cases that manufacturers may not have anticipated. These “inbound” customers, who come from outside traditional channels, bring fresh demand and insights that can drive innovation.

Configurator of Alfa Laval plate heat exchanger

-

- Flexible Product Development: As market demands evolve, configurators empower manufacturers to swiftly update product lineups and adjust available options. This adaptability ensures companies can remain competitive by quickly seizing new market opportunities and aligning product offerings with changing customer expectations.

- Service Stabilization: Standardized configurations not only enhance production efficiency but also simplify maintenance and service operations. Products built on modular, standardized configurations can often be upgraded or restored to optimal performance simply by replacing key parts, extending product lifespan and adding value for customers.

- Promoting Digital Transformation

-

- Integrated Systems: Configurators play a critical role in digital transformation by connecting seamlessly with key enterprise systems, such as Enterprise Resource Planning (ERP) and Product Lifecycle Management (PLM). This integration digitizes the entire manufacturing process, creating a unified flow of data that enhances transparency, consistency, and efficiency across departments. By linking with ERP and PLM systems, configurators ensure that data remains accurate and up-to-date, driving informed decision-making and streamlined operations.

While configurators have the potential to deliver exceptional results in the manufacturing industry, many companies have yet to realize their full benefits. Despite clear advantages, the adoption and implementation of configurators have often been slow and challenging. Why, then, is the introduction of configurators progressing so gradually in practice?

Why Configurator Implementation Alone May Not Improve Business Processes

The introduction of configurators has not always led to improvements in business processes. In some cases, companies have reported limited success, and in markets like Japan, there are few positive case studies demonstrating the effective adoption of configurators. Many companies remain uncertain about their potential benefits, which has slowed implementation. Several key challenges may contribute to this:

-

Catalog-Based Configurators: Most configurators are structured around a product catalog, emphasizing performance and technical specifications rather than aligning closely with customer needs. This approach often requires users to manually translate customer requirements into specific product attributes, which limits the configurator's efficiency and effectiveness.

-

Configurators Focused Solely on Quotation Simplification: Configurators that are designed primarily to streamline the quotation process can fall short of their full potential. While they may reduce sales administrative work, these configurators often lack the adaptability needed to address the diverse preferences that customers bring. As a result, they fail to add meaningful value to the sales process or enhance customer satisfaction.

-

Limited Configuration Flexibility: Some configurators rely on basic “If-Then-Else” logic, lacking the advanced, customized logic necessary to create complex configurations. This limitation is especially common in in-house developed configurators, making them cumbersome and restricting their usefulness.

-

Complex and Infrequent Maintenance: The more complex the product, the more intricate the configuration logic required. This complexity often results in infrequent maintenance, causing the configurator to quickly become outdated and less effective over time.

-

Lack of Integration with Other Systems: Without integration with key systems—such as Customer Relationship Management (CRM), Product Lifecycle Management (PLM), and Enterprise Resource Planning (ERP)—configurators operate in isolation. This creates data silos across the organization, requiring additional resources to manage data conversion and integration. Ideally, a single, centralized product database should serve all systems to maintain data consistency and streamline operations.

Building the Ideal Configurator

In an optimal setup, the ideal configurator operates within a Configure-to-Order (CTO) framework. This means the configurator is embedded within a company’s processes and closely aligned with an enterprise-wide approach. Rather than functioning as a standalone system, an effective configurator serves as a core process tool integrated throughout the organization. The diagram below illustrates this end-to-end CTO process, where the configurator is built on a foundation of standardized product data defined in advance by the company.

The ideal position of a configurator in a company

As the diagram shows, the configurator’s core data should ideally be grounded in modular planning and design principles, with customer needs serving as the guiding element. By pre-defining modules based on anticipated customer requirements, the configurator can effectively address a wide range of needs, enhancing responsiveness and flexibility.

Additionally, Modular Management recommends storing all product configuration data in a centralized product architecture model, which every department can access and utilize. This centralization ensures consistency and alignment across the organization. Each department’s systems — whether engineering, sales, or production — should draw from this same data source, enabling seamless collaboration and streamlined decision-making. For further insights, Modular Management’s guide on the secrets to business success through product configuration is available here.

Product architecture data sets are placed at the center of the company to connect between organizations.

To successfully implement a configurator, modularization of both the product and company processes is essential. In an ideal scenario, modularization is completed first, creating a structured foundation for the configurator to function effectively. However, this approach often requires a significant upfront investment, and companies may need to wait for some time before seeing a return in profitability from the configurator.

That said, introducing a configurator as part of a phased approach to modularization can yield benefits early on. While full modularization enhances configurator functionality, it is not an absolute prerequisite. Introducing a configurator within a defined modular scope can support incremental gains and pave the way for more extensive modularization efforts.

To do this effectively, companies should first clarify their strategic direction and define both a business and product roadmap. This roadmap can guide the gradual transition from the current product line to a modular product line. With a clear foundation and phased implementation plan, companies can align configurator and modularization efforts to maximize value over time.

Given this phased approach, implementing a modular project with an initial configurator setup can serve as an effective starting point. Starting with the configurator allows the company to begin realizing some benefits while building toward a fully modular system. With this in mind, consider the recommended approach illustrated in the following figure.

Example of modularization and small-scale start-up, with the configurator introduced first

Proposal for Implementing a Configurator Environment with a Phased Approach

To introduce a configurator as part of a gradual digital transformation and modularization strategy, we recommend a three-step process:

-

Utilize Standard Sales Configurator Functions for Quote Coverage

Begin by covering a significant percentage (xx%) of quote responses using the standard functions within the Sales Configurator. This initial step helps automate quoting and order processing, creating efficiency gains early in the process. -

Promote Modularity to Expand Coverage

As modularity develops, aim to cover over 95% of cases (xx% + yy%) through the Sales Configurator. Expanding modularity at this stage ensures that the configurator can handle an increasing range of configurations, which supports more extensive customization and consistency across product variants. -

Leverage API Integration for End-to-End Digital Transformation

The final step is to use the configurator’s API to handle 95% or more of order cases, enabling seamless digital transformation from order BOM to manufacturing BOM. This integration will bridge the gap between sales and production, facilitating automated, accurate data flow and minimizing manual intervention.

This approach assumes that the Digital Transformation (DX) of current product processes will reduce indirect sales hours, freeing up resources for further modularization projects. The key here is to focus DX efforts on the areas of business that will yield the greatest impact.

Finally, ensure that the configurator software can integrate with your existing systems, such as CRM, PLM, and ERP, through APIs. This connectivity is essential for maintaining a cohesive, centralized data environment across your organization.

Product Architecture Management and Configurator System

Modular Management, experts in modularization, offers the PALMA system — a comprehensive platform for managing modularization methods and product architecture. With the major release in May 2024, the PALMA system now includes a standalone configurator, known as PALMA Configurator. This modular tool can be deployed independently, making it an ideal candidate for organizations looking to introduce a configurator as part of a phased modularization strategy. PALMA Configurator is well-suited to support modularization planning, offering flexibility to scale as the company’s modular architecture evolves.

Summary

In this article, we have explored the configurator as a central goal of modularization, discussing both the benefits of implementing a configurator alongside modularization and the challenges that may arise. Modularization is not simply an academic exercise; it is a strategic initiative with a direct impact on a company’s profitability. Therefore, successful modularization should always consider both market demands and the unique internal environment of each organization, including potential conflicts of interest.

As companies embark on their modularization journey, I hope this insight encourages a thoughtful approach that balances immediate gains from configurator implementation with a long-term modular strategy that aligns with business objectives.

Want to know more?

If you find this topic interesting and want to know more about how we can help please get in touch with me. I'll be happy to set up a meeting to further the conversation.

Tadashi Matsuo

President Modular Management Japan

References:

- Design Rules: The Power of Modularity: Carlis Y. Baldwin Kim B. Clark, translated by Haruhiko Ando

- Tacton systems:Siemens Energy Reduces Quoting Time from 8 weeks to Minutes

- Alfa Laval Website: Brazed Plate Heat Exchangers

- Modular Management Website: The Secret to Business Success with Product Configuration (modularmanagement.com)