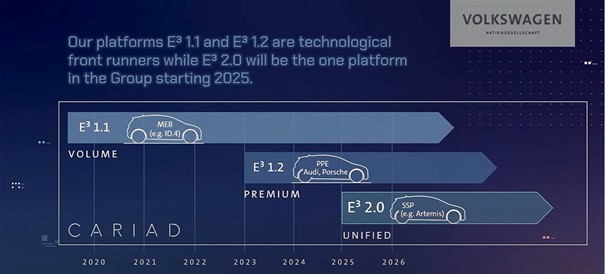

The other day I saw an excellent presentation about the Volkswagen Group 2030 strategy. The basis for the whole presentation was developing the SSP mechatronics platform and the E3 2.0 unified software platform. Platforms targeting to fulfill the need of all Volkswagen Group cars in the future. It struck me that VW is turning the fork around. When most other companies I meet in my daily work are adding more and more product platforms over time, either by acquisition or new development, VW is consistently reducing. And they have been doing so for decades.

How could others learn from Volkswagen Group? How could you keep track of your platforms and consistently reduce the complexity? How can you stop adding to the already heavy complexity burden? How could you turn the fork?

Volkswagen Group SSP, reducing the number of product platforms from 5 to 1. Source: https://www.volkswagen-newsroom.com/en

Volkswagen Group SSP, reducing the number of product platforms from 5 to 1. Source: https://www.volkswagen-newsroom.com/en

Business leaders tend to know and repeat that measuring is knowing and that you get what you measure. But honestly, how many (bigger) business leaders know by heart how many platforms they have in production today and how many they had ten years ago? How many know about the number of unique part numbers in ERP, and how many they plan to have two years from now?

You measure profit margins and returns, net sales, and CAGR. But these KPIs are not directly related to the underlying asset of the company – the product. Targets are often set on a very consolidated and lagging level. Some companies have realized that by measuring and controlling the complexity of your product, you will gain a sustainable competitive advantage; most haven't. By reading this blog post, I hope you will end up in the first category.

"Control and limitation of part numbers is one of the more important factors for profitability."

But, before digging into how to measure the product platform performance, let me explain first what modularity is and why modularity is a key factor for product platform performance.

What is Product Platform Modularity?

Modularity is the degree to which a system is modular. A more modular system requires fewer building blocks (Modules) to create the necessary variants (Products or Configurations). Vice versa, a less modular system will need more unique building blocks to satisfy the demand.

A product platform with a high degree of modularity is typically more efficient than a comparable product platform with a lower degree of modularity. In this post, I will use Product Platform and Modular System synonymously. More parts will be re-used across different products configured on the product platform.

Modularity has historically been used predominantly for products consisting of hardware and mechanics. Today modularity is heavily used also for software, electronics, and combinations thereof. It is also possible to describe the modularity of different professional services, e.g., logistics, banking, insurance, and consulting.

Simple examples of modularity can also be seen in our everyday lives. One such example is in our kitchen, where a limited number of staple ingredients allows us to create many different foods. Using ordinary staples like flour, water, milk, eggs, baking powder, and salt in various combinations, you could end up with pasta, bread, pancakes, or waffles. What would happen if you used a ready-made mix for each dish that you make – well, unless you standardize towards just a few dishes, you will run out of cabinet space quite soon!

Modules?

While it's easy to find examples of modularity and understand the basic concept, most companies are not measuring and following their performance regarding modularity. Even though modularity is a clear indicator that, when controlled and optimized, can give considerable improvements to the business.

What are the Benefits of Modularity?

The benefits of modularity can be seen in all parts of the value chain. Let's look at some examples:

Less work will be needed when a product is designed if some parts can be re-used across many products. Let's assume we are designing a product platform for electric power tools. If we can re-use the same battery across all products in the product platform, we only have to design one charger, one battery, and one battery compartment.

Sharing modules across products has positive effects both internally and externally

Sharing modules across products has positive effects both internally and externally

In the next step, the purchasing department gets a shorter list of unique parts to source, meaning that they need to find fewer suppliers, make fewer price negotiations, and write fewer contracts.

Planning will become easier within inbound logistics, and material handling with fewer variants and storage space can be used more efficiently with fewer items to manage.

In assembly, a higher degree of modularity means that fewer unique parts can build a flexible assortment – perhaps a single flexible line can assemble all different types of products in the product platform. Material supply will become easier, and tooling can be streamlined. It also reduces the risk of selecting the wrong component for the assembly worker.

A higher degree of modularity within sales means that products are flexible towards different customer needs and can be carefully adapted to the specific sales case.

For the customer, the higher degree of modularity can have many positive effects. The battery example is one such example. Sharing batteries across products means that the customer can have fewer batteries in total and fewer chargers. They may also be more readily available in the aftermarket when a replacement is needed. Increased modularity can also increase the familiarity with the user interface to operate the appliance.

Aftermarket and service is a function where increased modularity can have huge effects. If each product and generation is designed from scratch, the aftermarket will soon have an endless range of spare parts to have readily available. The service technician will need to have extensive competence to service all different products and tools.

In a circular economy, increased modularity could even let us separate, refurbish, and re-use components once the product reaches its end of life. Read more about How to Design Products for the Circular Economy

Are there Downsides to Modularity?

Modularization is a methodology, and as with any methodology, it can be misused. If you have read my blog post on optimizing the number of variants in a module system, you know that working with industrial operations is a game of volumes. And modularization is a methodology to get scale on modules, even though the products are unique. With this in mind, we can easily understand that depending on the volume, there is a risk of pushing modularity too far (if by modularity, we mean high commonality).

Using a standard pump, for example, can be a terrible choice for an appliance manufacturer making millions of washing machines annually. But for another company, producing 25 fuel treatment skids a year might be by far the best choice. The difference in magnitude of volumes tilts the relation between annual material cost and the annual cost of complexity. For the appliance manufacturer, adding 50 cents to each unit adds up to millions every year. For the fuel treatment skid supplier, it’s only 12.50.

KPIs to Measure and Control Product Platform Performance

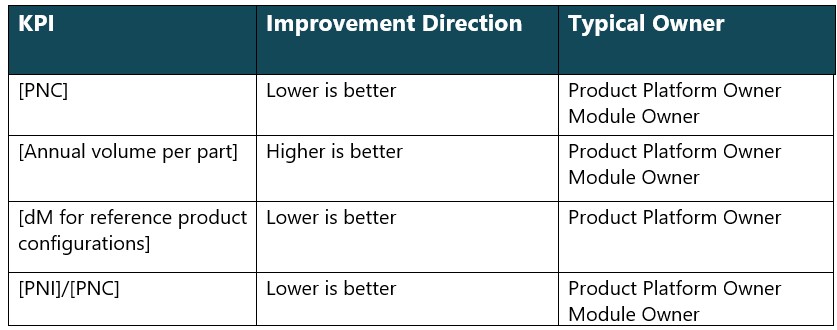

Now that we have discussed the benefits of modularity and possible downsides, it's time to discuss how to measure it. As always, when talking about measuring and controlling stuff, i.e., KPIs, we want to ensure that our KPIs lead us in the right direction. We can measure modularity on different levels, and it's important to take a step back to understand what type of decisions will be influenced by the KPIs.

Company Level

Product Platform Efficiency

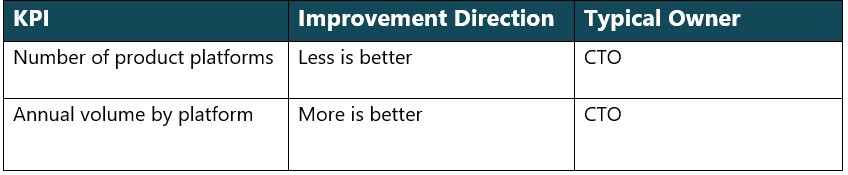

On the company level, decisions are made about how many platforms to have. When developing a new product, R&D management often needs to decide to do so by evolving an existing platform or by developing a new one. Sometimes companies decide to fork existing platforms by only updating parts of the platform, which results in more platforms to maintain and produce. The number of platforms can have extreme effects, such as whole supply chains, development centers, etc., being tied to the existence of a platform.

Measuring the number of product platforms works fine for Software as well but is typically called software architectures or software platforms. In many businesses, there is a clear trend towards replacing multiple product-focused monoliths with a single unified and modular software architecture. One such example is Volkswagens E³ 2.0:

Volkswagen Group is implementing a unified software platform across all brands. Source: https://www.volkswagen-newsroom.com/en

Volkswagen Group is implementing a unified software platform across all brands. Source: https://www.volkswagen-newsroom.com/en

Suggested KPIs for Product Platform Efficiency:

Modular System/Product Platform level

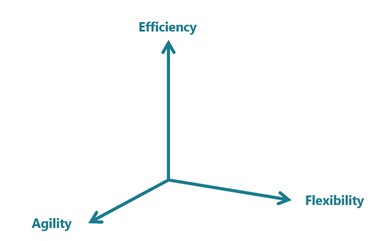

There are three fundamental targets for any product platform, increasing flexibility, agility, and efficiency. These are the targets we want to measure and control to enable efficient steering of the business.

The three fundamental targets of product platforms and architecture: Efficiency, Agility, and Flexibility. Which one is most important to you?

Flexibility

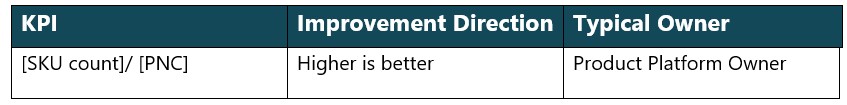

Doing more with less is something often said about modularity. The modular system needs to be flexible to allow configuration of many different value-adding product variants for this to happen. For a product-focused company with a product catalog with Stock Keeping Units (SKUs), we want to ensure that we need a few unique parts per SKU as possible. The number of unique parts is measured by counting them in the ERP system. I have referred to it as Part Number Count (PNC).

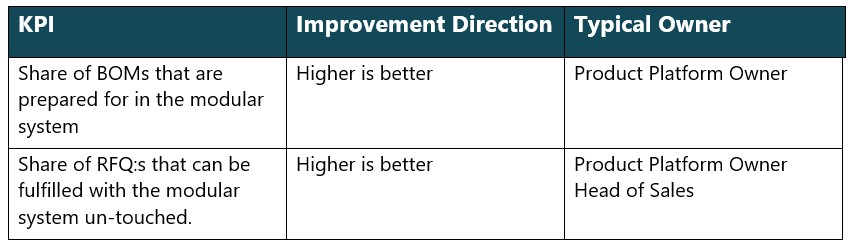

For companies selling configurable products or project-oriented companies, the SKU count is not a meaningful measurement. Even though the company only sells a limited number of products every year, the possible combinations could be practically endless. For these companies, my advice shifts the focus to the share of orders or share of the BOMs that are taken from the prepared/planned library of module variants. Increasing this share means that the system is flexible in a way that reduces order engineering. Combined with other KPIs to measure efficiency, this ensures that we steer towards a profitable system.

Suggested KPIs:

For product-focused companies:

For configuration/project focused companies:

Agility

Product platforms that are agile are prepared for change. To add new products or performance levels we need to change only affected modules, keeping the rest of the modules intact.

Just as with flexibility, we need to differentiate between product focused companies, and companies that configures/customizes each order.

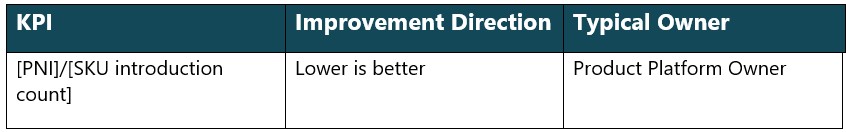

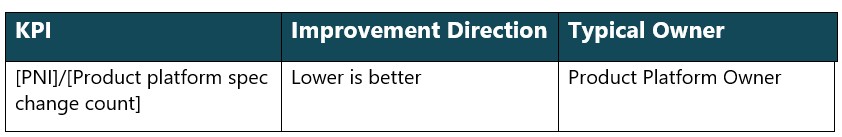

PNI is short for Part Number Introductions, it is the number of parts added to the ERP system in a year. By comparing the PNI with the number of added SKUs in a year we get an average of how many parts we need to add to introduce a new SKU. For configuring/customizing companies it is better to track changes in the platform specification. If we add a new specification for some property, it is a change to we want to accommodate with as few part number introductions as possible.

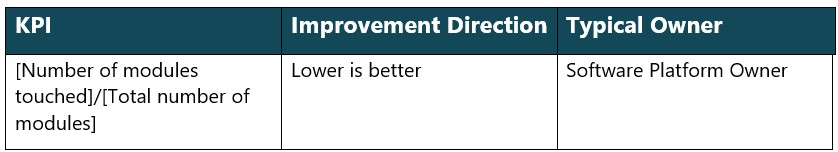

Perhaps the most interesting benefit of software platforms is the agility for change. By isolating modules that are strategically intended to change, from modules further down in the stack where change is complicated and often costly; each update will trigger fewer code updates. This means less work, less testing, and fewer quality risks.

One way to measure this is to track the number of times software modules are touched every year and relate it to the total number of modules. This way we can get an indication of how much of the code is changed every year. Better modularization and decoupling will lower this ratio. Note that one module can very well change much more than once a year. The target of modularity is not to hinder change, but to stop change from spreading to what can be kept stable. If strategies are defined for the SW modules, the touch rate can be measured and visualized by module type. It could also be related to the amount of change that we want to have, e.g. the number of customer value driving feature updates.

Suggested KPIs:

For product focused companies:

For configuration/project focused companies:

For software:

Efficiency

The third fundamental target with a product platform is to reach efficiency. Efficiency is enabled by reduced complexity, or to turn it around, increased re-use. As I have already discussed Part Number Count is a measurement of the complexity, and by tracking it over time companies can control the complexity growth. However, for high-volume companies it may be worth tracking the annual volume per part as well, since we want to allow more variants where we have volume.

At the same time as low complexity is something to strive for, companies must ensure to not sacrifice material cost efficiency to enable re-use. Because of this, it is a good idea to also track the direct material for some important SKUs/product configurations. However, most companies already track direct material cost in detail.

Agile systems have a lower number of part introductions for each new product. That makes development faster.

From the efficiency perspective introductions can also cause issues such as quality problems, supplier issues, and production issues. Typically, things stabilize and improve over time, and that's why we want the added parts to live as long as possible. To measure this, we can track the relation between PNI and PNC. This indicates the share of the parts that are added every year.

What's the Risk of Not Measuring Modularity?

As Lord Kelvin said back in 1883; when you cannot express your knowledge in numbers, your knowledge is of a meager and unsatisfactory kind. The risk of not knowing is making the wrong decisions. If you do not know how much complexity you have and track it over time, there is a huge risk that you continue to add to it. If you do not know how many part numbers you have today, you will not know if you are better tomorrow. And you will have a hard time taking fact-based decisions about balancing performance, cost, and complexity.

There is also an important leadership aspect to it. What is measured in an organization is implicitly communicated as important. Helping to improve on KPIs is rewarded, either up-front, or indirectly. By communicating clearly and consistently, leaders can make champions out of the colleagues that work in the right direction and enforce decision models that stop decisions in the wrong direction.

Three Key Success Factors for Measuring Modularity

1. Know Your Vision and Targets

When deciding what to measure, you must know what you want to achieve. Why do you have product platforms in the first place? Setting the vision and reaching alignment in the top management team is the first requisite for success. Once you know what to achieve, you can design KPIs to measure it. It will also be easy to communicate why you track it, and what decision will be built on reliable data.

2. Keep it Simple

A typical failure mode of setting KPIs is to overshoot. There are too many KPIs tracked, and the definitions are too complex and data hard to consolidate. Start small, add as you go. Evaluate the need. The KPIs doesn't have to measure everything 100% correctly, they are there to support the steering of the business. A way to signal when things are going the right way, and when they are not.

3. Be Persistent

To really draw conclusions from the data you need a trail of measurements. Otherwise, you can't reliably tell which way you are going. Measuring and comparing to other companies is dangerous – you never know if you measure the same thing or if your operations are actually fully comparable. KPI measurements are most effective if we can see what has happened in the past, and plan for the future. And tracking the performance on the way there.

Summary & Conclusions

In this blog post I have explained first of all what modularity is and why you need to measure it. Based on the three fundamental goals of using product platforms I have suggested a number of KPIs that can help you on your way towards product platform excellence.

I hope that you will go back to your office and start measuring the complexity of your products and the performance of your product platforms. Perhaps start asking your colleagues questions about how their product platforms are performing. How many product platforms do you have in your company by the way? How many unique part numbers?

Want to know more?

Please contact us directly if you'd like to discuss the topic covered in this blog or looking for a sounding board in general around Modularity and Strategic Product Architectures.