As you already know, maximizing long-term profits for your company requires you to manage your portfolio of products with skill and finesse. But what if your product portfolio is based on a platform? What are the best practices and benefits in this case?

This article will give you the best tips and tricks to obtain the most profit from platform-based products.

Managing Platform-based Products, What Is So Special About It?

First, let us briefly explain what we mean by platform-based products. When products come from the same platform, they share design principles, technical solutions, and components to a high degree. You achieve synergies and speed in the development of the products with this approach. At Modular Management, we believe the best way to achieve such efficiency gains is to create a system of modules used to build the portfolio products offered to a range of customers in the market.

Platform-based products mean we need to manage not one but a whole range of products. At the same time, we strive to use the same designs and parts. Therefore, a few interesting questions arise:

- How do we differentiate the products on the platform to maximize sales while avoiding cannibalization?

- How do we supply information to the engineers so that they understand which aspects the products should differ in the specification, e.g., what can be common between the products and how will they evolve?

- How do we calculate, control, and optimize the profit of the product assortment?

In the next section, we will answer the three questions above.

Key Ingredients for Successful Portfolio Management of Platform Products

“How do we differentiate the products on the platform to maximize sales while avoiding cannibalization?”

The key to differentiating products clearly understanding the target customers’ needs. In our experience, most companies offer products sold to customers with different price and relative performance expectations. The products are used for slightly different purposes, and the customers are seeking various benefits from the products. For this reason, we stress to our clients the need to spend time understanding these differences. For example, do some customers prefer “Simple Installation” over “Long Product Lifetime”?

Understanding differences and similarities in customer requirements is especially important when managing platform-based products. You need to identify shared product areas. As the requirements are later turned into product specifications, vary the specification where it counts for the customers. Otherwise, you risk cannibalization.

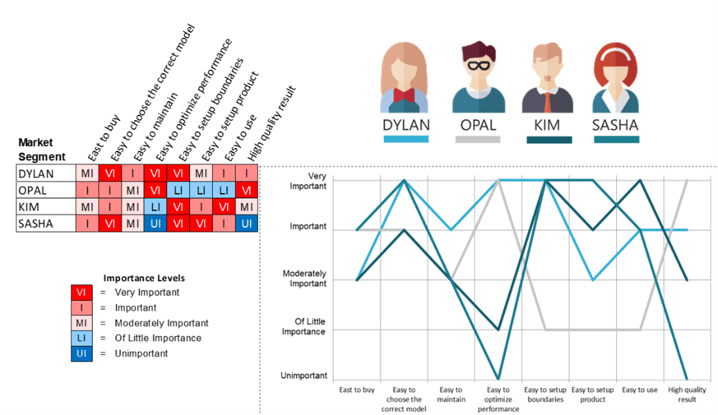

Example of differences in customer requirements which can be analyzed with the help of a so-called customer canvas

In conclusion, to successfully differentiate your products, start by carefully considering differences in the requirements of your target customers. In addition, differentiated pricing and managing product roadmaps are complementary product management methods that we will describe in a future article.

“How do we supply information to the engineers so that they understand which aspects the products should differ in the specification, what can be common between them and how they will evolve?”

Assuming the products have been varied in specifications, the next step is to convert the specifications into designs or code. A good product range specification should tell your engineers how the products differ and what is common between them. But first, the engineers must be able to understand the product specification and find it descriptive enough so that they can create the product designs. This seems self-evident but can be hard to achieve. Sometimes, product specifications go too deep and stipulate sub-optimal technical solutions, which only constrains and confuses the engineers. Whereas sometimes the specifications aren’t precise or describe environmental conditions that the product design cannot influence. For this reason, it is recommended that you create and review the product specification in close collaboration with your leading engineers. Another recommendation is to create a structure for the specifications that separate product requirements (e.g., speed, max width, etc.) from functions and technical solutions that are the domain of the engineers.

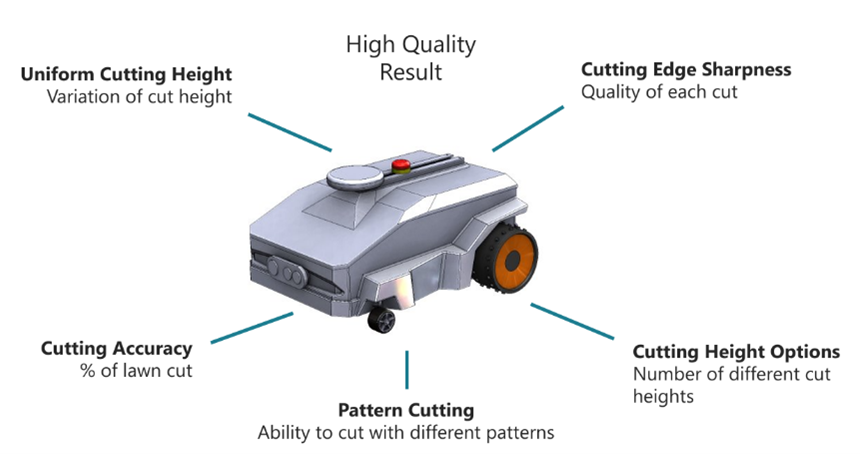

Example of product requirements in the form of product properties. A product property can be defined as a measure of a product that quantifies the delivery of benefit to customers. Each product property can have one or several goal values.

A successful product management organization closely collaborates with the engineering team to define product requirements in a structure that creates an internal common language for a complete product range. At Modular Management our structure to manage product requirements is based on product properties and goal values. Product properties and goal values are a very efficient way to inform engineers in which aspects products should differ in specifications, what can be common, and how they will evolve.

“How do we calculate, control, and optimize the profit of the product assortment?”

When products are successfully developed and implemented with a platform approach, they share many technical solutions, principles, parts, production lines, and tools. This approach is a game changer because it reduces the overhead cost of developing and producing the products. But to fully unleash these benefits, we need to change the way we calculate and control the cost and profit contributions of the platform. To maximize profits, we must move away from financially controlling single products to controlling the complete range of products that come from the platform.

This successful formula can be intimidating at first. To break the process down, we must:

- Calculate the cost of introducing and managing items that drive overhead cost, e.g., unique parts, production lines, tools, etc., and then map these items to the sub-assemblies/modules of the platform.

- Calculate the direct cost of the sub-assemblies or modules shared by the products in our platform. This step also includes correctly mapping these sub-assemblies/modules to the products use them.

- Establish average sales price and volumes of our products.

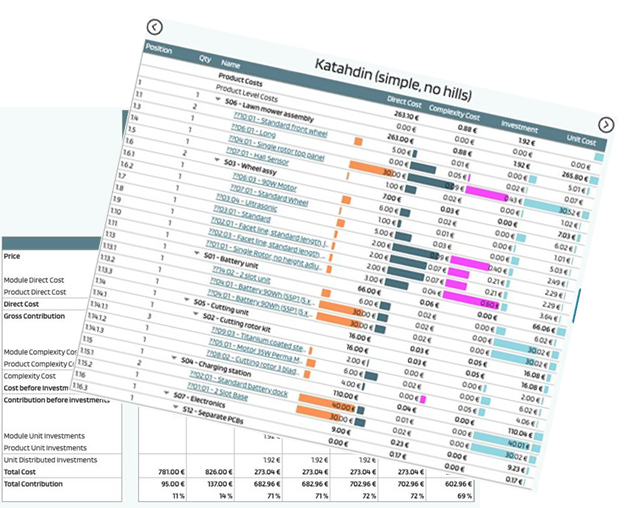

Example of product portfolio profitability control overviews that consider cost of complexity when developing and producing the products.

Combining input from Steps 1-3 will give us a simplified income statement for the whole product platform. Properly compiled, we should be able to simulate impact on profit when we introduce or remove a product variant or a sub-assembly to/from the product platform. Overall, this profit and cost control level will prevent sub-optimal decisions for the product platform compared to just measuring profitability on a product-by-product basis. In short, it will allow you to obtain the most profit from a portfolio of products based on a shared platform.

Summary: Well-structured and Linked Product Architecture Data is the Key to Successful Product Configuration

As stated in the beginning, platform-based products requires the management of several distinct products along with their shared designs and parts. These requirements can be demanding for product portfolio management. We believe the most efficient approach is the application of a combination of 1) product requirements that describe with precision the commonalities and variances, 2) cost and profit controlling for the whole platform that considers the cost of complexity 3) a close teamwork between product management and engineers.

Want to Know More?

If you want to know more about the specific topics mentioned in the article? We would love to discuss with you how to optimize your product portfolio to maximize profits. Give us a call or send us an email to take the first steps to increase your portfolio profitability!

AUTHOR

AUTHOR