Modularization is a tool that increases speed when creating a range of designs while improving robustness by limiting the impact of changes. Modularity can be applied to different scopes, be it sub-systems or complete products, but also company-wide across products.

Modularity is a structured and organized system with controlling rules called an Architecture. Individuals working with a Product Architecture should be well educated in the governing principles so they know how to comply and enforce the architecture-, i.e., no spur-of-the-moment changes or experimenting in what and how to design. The benefit is that people are free to act autonomously within the architecture, which will be efficient and require minimal effort with a guaranteed outcome.

The wider the scope, the larger the benefit; this is why company-wide modularization should be your ultimate goal. PALMA’s Systems of Systems capability ensures effective cross-platform management of product platforms and families so that your organization can focus on harvesting the effects of the synergies. Learn more about the capabilities of Systems of Systems and its benefits to companies below.

Why Modularization is More Effective Across Platforms

A modular system assigned to a product is designed to generate product variants with similar technical and supply chain-specific properties. The scope of the modules is limited to the modular system of the respective product. A company usually develops and manages several modular systems to serve different product families or platforms.

While modularization simplifies the development of new products within the modular system, it also restricts cross-platform opportunities. Companies are missing a vast opportunity as synergies between product platforms or families are not considered.

A higher level of modularity is required to share subsystems across a company’s entire product portfolio, what we refer to as company-wide or cross-platform. Such subsystems can be managed as Modular Systems which other Modular Systems can reuse. These modular systems can range from complex configurable subsystems to single modules with a common range of variants. This structure of reuse results in information shared in a network of modular systems, also known as Systems of Systems.

Systems of Systems: Definition

In the context of modular product architecture, the term "Systems of Systems" describes a system architecture of several modular systems. This can be a network of module systems sharing information according to some of the statements below:

- Each module system can be configured independently but doesn’t need to be.

- There can be a hierarchical structure, a breakdown of a more extensive product.

- It can be a system or sequence of equipment or products that should work together.

- There can be independent subsystems shared as complete systems.

- There can be repositories of reusable elements shared in packages.

Companies adopting Systems of Systems to manage their product portfolios intelligently enjoy advantages such as:

- Greater economy of scale and complexity costs optimized across the company.

- Process efficiency by well-organized and reusable data rather than overlapping and redundant data.

- Manageable product data in an ever-increasing product offering.

Systems of Systems: Industry Applications

Cross-platform architecture is gaining a lot of momentum in the automotive industry, where companies even promote it in their marketing. A Systems of Systems approach also benefits other industries, such as industrial equipment, household appliances, and even furniture.

Scenario 1: Shared modular systems

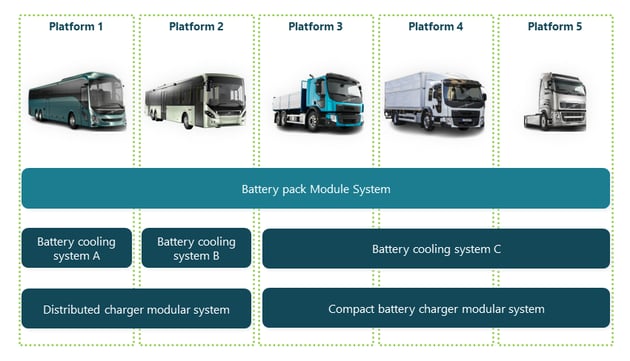

A modular system can be used in several product platforms, and a product platform can use several modular subsystems. One example could be a modular battery system deployed in different commercial vehicles platforms, like city buses, coaches, and trucks.

Example: Modular battery system used in different vehicles

Scenario 2: Complex product portfolios

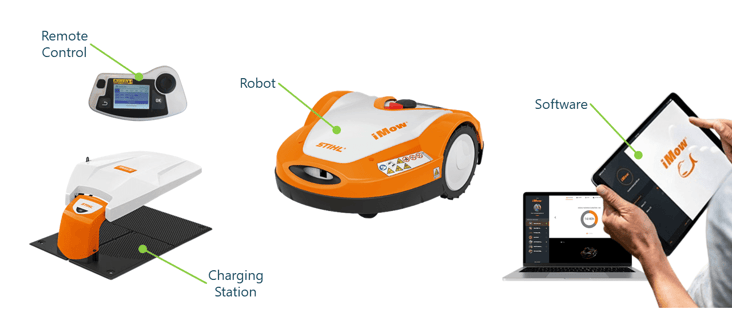

Complex products usually have several independent subsystems. These are often divided by design disciplines, such as mechanics, hardware or electronics, software, or mechatronic systems. They can also be divided by geometry or how the product is sold.

One example of this could be a robotic lawn mower. Here, it would be possible to design the appliance, remote control, charging station, and operating software as separate modules of the same module system. When adopting Systems of Systems, these would rather be different modular systems linked together. This allows the company to offer the charging station and the remote control as stand-alone products and bundles with the main product. The company’s other appliance products could also use the software.

Example: Modular systems of a robotic lawn mower

Example: Modular systems of a robotic lawn mower

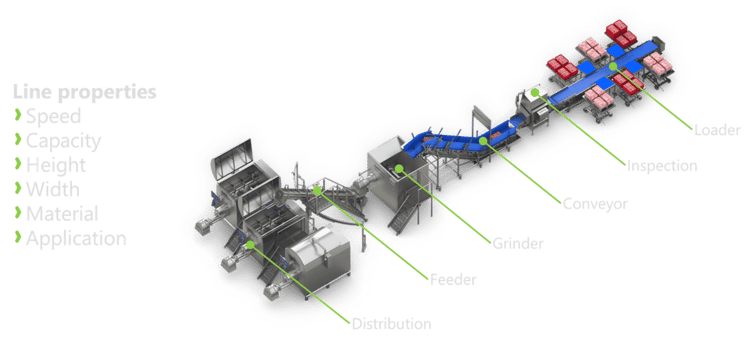

Scenario 3: Configurable production lines or systems of equipment

Companies offering equipment or products intended to be used together in a system or production line need to comply with the overall performance or functional properties. To achieve this conformity, each product or equipment’s module system must use a common dictionary or definition of properties.

One modular system is used to dimension the system or line. This module system will set the common attributes and performance limits for each subsystem, product, or equipment.

As each individual module system is configured, these overall or global properties are set. The effect of each property will be different for each equipment’s module system.

This method manages complexity by dimensioning the system’s total performance and configuring the individual equipment. The overall performance and functionality constrain each system’s equipment.

Example: Production line consisting of several equipment

Example: Production line consisting of several equipment

Systems of Systems: Success Factors

Managing data and ownership within a Modular System while optimizing complexity, including reducing costs and economies of scale, can be challenging within a product platform or family. Expanding the scope to cross-platform or company-wide, the challenges increase by magnitudes.

To be successful, a company needs a dedicated tool for Systems of Systems to achieve this capability. This includes tracking dependencies and keeping financial models up to date through the development and usage across module systems. Users need to be protected from the complexity of managing data integrity, or it will quickly erode.

How do Systems of Systems work in practice? And how is data managed and shared?

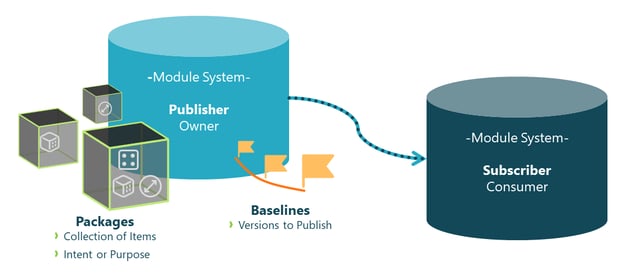

Ensure data exchange between modular systems

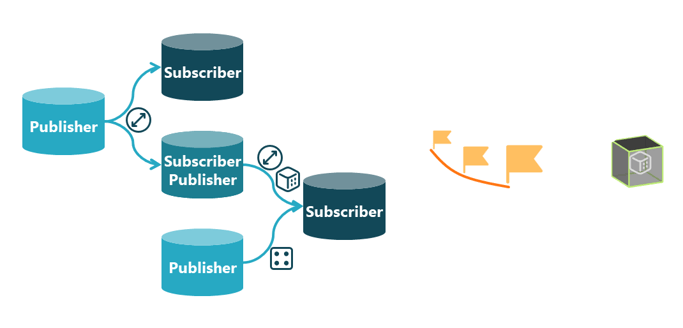

Data exchange between module systems is based on an Owner module system that publishes data to a Consumer module system that subscribes to data. Data is collected into published packages, where each package has a purpose or intention for its use. As data evolves, it is critical to control what version of the data is shared through published baselines.

Example: Interaction of subsystems in the Systems of Systems

Every exchange between two modular systems requires one Publisher and one Subscriber. The Subscriber selects Publisher and Baselines and which Packages to subscribe to.

The Publisher owns the data and can publish more baselines as data evolves. The Publisher can add more packages or update existing packages by adding or removing information. The Publisher can also remove or revoke packages.

Example: Data integrity is maintained by baselines and packages

Example: Data integrity is maintained by baselines and packages

Data integrity is always enforced with this framework. As published information is changed, the subscriber will be notified of new baseline or outdated packages, which enables the Subscriber module systems to be updated in a controlled manner.

Finding the right software for the cross-platform modularization

The key to cross-platform modularization is a tool that supports you with all the challenges of sharing data and keeping financial models up to date.

PALMA’s Systems of Systems capability is the solution you are looking for.

Example: Systems of Systems with PALMA gives layered access and version control

PALMA is developed to manage modular systems across platforms as an out-box, ready-to-use SaaS solution for strategic and data-driven product management.

Want to Know More?

Our product architecture experts demonstrate how to use PALMA to manage modular subsystems and use them to develop new products in the webinar "How to Manage a System of Modular Systems? and Why?"

Additionally, to learn more about Systems of Systems, PALMA, or request a demo, please contact us.

AUTHOR

AUTHOR