CASE

Reduced Complexity with A Modular Product Architecture

The Sidel Story

In the face of increasing complexity and aggressive competition, Sidel CEO Mart Tiismann decided to invest in a modular product architecture program. The results were remarkable.

Sidel is the leading global provider of PET solutions for liquid packaging. The company is market leader in blowing, filling, labelling, material-handling and line-engineering solutions for the beverage, food, home and personal care industries.

In 2010, Sidel was struggling with a complex assortment and high costs for order engineering. Since the company sells both complete lines and individual subsystems, a relatively high degree of product complexity and order engineering can be expected. Yet the situation was made worse by a Sales culture of saying ‘yes’ to all market requests for customization, and this was more than a question of culture. The market needed more configurable solutions.

While Sales was saying yes, Engineering and Supply were having a hard time delivering what was sold and the competition was heating up. Margins were under pressure, not least as the competition ate into the most lucrative customer segments, geographies and solutions.

In the face of increasing complexity and aggressive competition, Sidel CEO Mart Tiismann decided to invest in a modular product architecture program. The results were remarkable:

- 60% of solutions sold were now configure to order – up from 33%

- 40% reduction in part numbers

- 50% fewer new part introductions

- 10% in reduced cost

- >300% in product assortment configurations

- 30% reduction in total cost of ownership

- 50% shorter order to delivery lead time

- 30% shorter time to market

- 80% reduction of engineer to order hours.

As CEO of Sidel, I learnt that it’s possible to transform a business by connecting products, customers and organizations. Modular product architecture and information management tools made it possible.

As CEO of Sidel, I learnt that it’s possible to transform a business by connecting products, customers and organizations. Modular product architecture and information management tools made it possible.

Mart Tiismann, Former CEO of Sidel Group

Company Situation

In 2010, Sidel employed 5,300 individuals and generated a revenue of EUR 1.4 billion. The company specialized in engineer-to-order operations across its 26 facilities, dedicated to a comprehensive range of liquid bottling processes including blowing, filling, capping, labeling, and conveying.

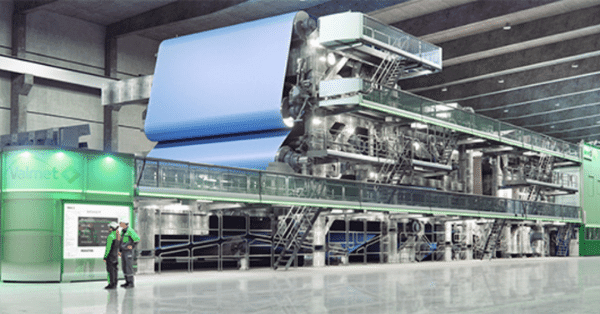

Sidel's extensive product lineup encompasses complete packaging lines and individual subsystems necessary for liquid packaging. This includes blow molding machines, fillers, conveyors, labelers, pasteurizers, palletizers, depalletizers, robotic equipment, and end-of-line solutions, supplemented by a full spectrum of services and spare parts.

The systems offered by Sidel are recognized for their innovation, size, complexity, and high-precision engineering. Constructed using premium materials, these systems require substantial and costly spare parts. They operate at high speeds and maintain stringent tolerances.

By 2010, the company's commitment to customized, order-engineered products led to a significant degree of customization in production. Remarkably, one in every three products featured some form of new design or innovative feature.

Reduce Costs, Increase Market Share and Increase Price Premiums

Sidel's Challenges

In ‘The Discipline of Market Leaders,’ Treacy and Wiersema present three value disciplines: Operational Excellence, Customer Intimacy and Product Leadership. This is the transformation model Mart Tiismann focused on together with Modular Management’s Alex von Yxkull and Alex Ginsburg.

Both challenges and targets for the Sidel modularization program were structured according to the value discipline model with the goal of reducing costs, increasing market share and increasing price premiums.

Sidel’s business challenges were analyzed and summarized as reasons why the company wanted to initiate a modularization program. Each challenge was allocated to a specific value discipline.

Product Leadership Focus

- Need to focus more on innovation – and less on redesigning parts – to regain market leadership.

- Cross–fertilization and use of innovation partners will demand a modular product architecture and defined interfaces

- A solution range based on derivates of a standardized base model will leave too many holes and unpredictable complexity costs.

Customer Intimacy Focus

- Standardization of the product offering does not work

- Order engineering is too slow and expensive.

Operational Excellence Focus

- Too many parts and too many suppliers make systematic improvement impossible

- Unstable designs make a truly global supply chain impossible

- Complexity costs are much higher than understood

.

Reduce Complexity and Improve Technology Leadership

Goals for the architecture development program were set according to the same value framework as the challenges.

Product Leadership

- Improve technology leadership

- Reduce time to market

- Improve performance, primarily speed of new product introduction and improved total cost of ownership.

Operational Excellence

- Reduce lead times

- Reduce complexity costs through fewer parts needed

- Enable the splitting of design, sourcing and assembly across different geographical locations

- Enable increased reuse and reduce customer–specific engineering

- Improve quality.

Customer Intimacy

- Enlarge the product offering

- Better serving the increasing variety of customer requirements

- Enable the development of services.

Program Scope

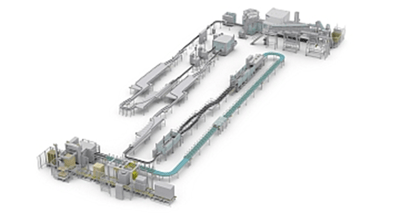

The scope of the modularity program was Fillers, Blowers, Conveyors and Labellers and focused on:

- Need for market-driven variance and development

- Complete line configurations, harmonization and balancing of performance

- Equipment internal modularization and compliance to complete line interfaces

- Additional focus on control systems (complete line and equipment)

- Process and information management for maintaining modular products

- Process and information management for configure-to-order.

Program Results

Product Configurations

Sidel’s new modular product architecture included the building blocks, or module variants, needed for a better and bigger product assortment. Product–specific results included:

- More solutions on offer, including triple the number of blower products

- More options available on more products, thanks to standardized interfaces

- Aligned product ranges, with specifications defined at complete line level

- Three conveyor ranges were moved to one architecture, leading to better performance and a higher degree of configurability – without increasing complexity – and 30% fewer new part numbers.