CASE

Fit-for-purpose vision with Modularity

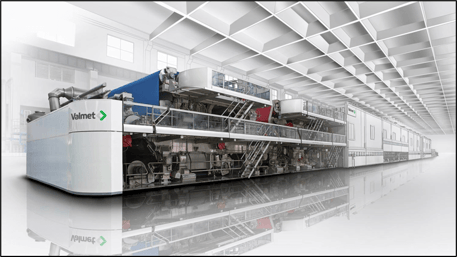

Valmet Paper Machines - Infinite Variance

Valmet is the world market leader within the field of board and paper machines.

These machines are complex and each one is unique.

The paper market has shifted over the last decade from paper grades, used for newspapers and print, towards board grades, used for packaging. The paper machine market has also developed towards lower technology levels and faster payback times and low-cost suppliers have entered the market.

These market developments were challenging, and Valmet formulated the “fit-for-purpose” product vision as a countermeasure, to continue meet customers’ different needs, but at a considerably more competitive cost level.

Fit-for-purpose vision with Modularity

Valmet saw opportunities with modularity early on and made certain first achievements on its own. In 2012 Valmet engaged Modular Management to make a deeper analysis of how Valmet could fulfill customer’s requirements with a modularized product portfolio and how to stage the journey. The three months study showed large cost-efficiency potentials through the value chain, from sales, via order engineering, production to installation, and start-up. Based on the analysis Valmet decided to use modularity as the tool to implement the “fit-for-purpose” vision.

Valmet and Modular Management started with modularizing one of the key sections of the paper machine. The focus was especially on lowering engineering, procured material, and production cost while keeping a high degree of customer and product flexibility.

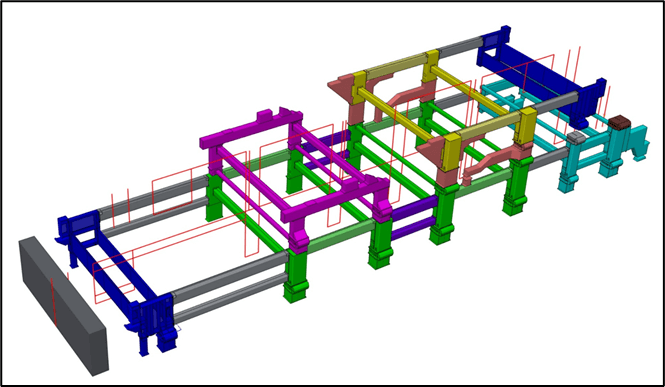

The cross-functional development team created many new solutions, one being the modular frame structure. The new frame became lighter, easier to produce, and more cost-efficient. It also includes fewer unique parts to build the many different section variants.

Illustration: A modular frame structure

Achieved Result with Modularization

Over the following years, the journey continued with modularization of the other seven sections of the paper machine, with comparable achievements. The increased repetition, reuse, and reduced need for order engineering have enabled:

- Reduced lead time and cost for the engineering work.

- A more thorough design-to-cost work, reducing both weight and thereby raw material cost as well as production cost for cutting, welding, machining, etc.

- A more industrialized production setup, with batch purchasing, standard routings, and standard operations, jigs for welding, machining, and assembly, etc.

- In cases, the production set-up has changed from a functional workshop, with crisscrossing flows, many movements, long lead time and a high level of work-in-progress to product flows with improvements in quality, lead time, and cost.

- Logistics and installation are less complex to manage.

The Digitalization Journey

Digitalization is the next big leap driving business efficiency at Valmet. Digitalization, with the purpose of decreasing the amount of manual touch points, is challenging when dealing with complex and flexible systems. With an engineer-to-order setup the challenge increases tenfold. The modular paper machine has laid the foundation to cope with this challenge, as it caters for rule-based configuration of pre-defined or parametric parts into countless product variants.

The digitalization journey is ongoing, and the envisioned results include:

- More controlled and robust process at the handover between sales, engineering, and supply chain.

- Increased cost efficiency and reduced lead time through the value chain

Valmet’s paper machines management team has made modularity a cornerstone of its operation’s development, including the digitalization and “fit-for-purpose” visions. The organization continuously delivers achievements within the Modular Way program for the benefit of Valmet’s customers, owners, and employees.

“The modularity has been quite a transformation journey for us over the last years, and I´m very glad we recognized early on the need for a proper partner to support us. We have been impressed with the professionalism and know-how Modular Management has brought to the project as our partner, and the deep cooperation has continued ever since. We have achieved great concrete developments so far and aim for ever higher in the future”.

Petri Rasinmäki, Vice President, Board and Paper Machines Technology Unit at Valmet