Why ETO Keeps Costs Growing—And What Most HVAC Manufacturers Miss

Many HVAC manufacturers don’t realize the true impact of ETO until they step back and look at the big picture. The costliest part of ETO isn’t the engineering time or manufacturing inefficiencies—it’s the way it locks the business into an ever-expanding complexity cycle.

Every new order brings new variations of components, new sourcing requirements, and new production constraints. This not only increases costs—it makes scaling the business harder over time.

Hidden Complexity in ETO Models:

-

Procurement challenges: More unique parts mean weaker supplier leverage, unpredictable demand, and excess inventory.

-

Engineering bottlenecks: Custom solutions force engineering teams to work reactively instead of strategically.

-

Manufacturing inefficiencies: Frequent changeovers, low-volume production, and complex assembly increase operational costs.

So why do companies stick with ETO? Often, many believe that they can make it work by breaking up their solutions into modules, enabling separate teams to focus on each but they have only scratched the surface of what is possible.

|

So You Think You’re Already Modular? Many HVAC manufacturers think they’re already modular—after all, their products use familiar subsystems like compressors, heat exchangers, controls, and structural elements. But using standard components isn't the same as having a strategic modular product architecture. A truly strategic product architecture is more than just breaking a system into technical chunks. It's a long-term business asset that shapes how you compete and grow. A modular architecture that produces real business results does more than break a product into pieces—it:

If you’re still redesigning products for every order, your modularity isn’t strategic or driven deeply enough into your products. |

The Solution: Moving from ETO to CTO with Modular Product Architecture

The Key Shift? Instead of engineering every order from scratch, a well constructed modular approach enables Configure-to-Order (CTO) which maintains the flexibility to meet individual customer needs while significantly reducing costs.

By structuring your HVAC product portfolio around pre-validated, configurable modules, CTO allows for:

- Common parts and modules that eliminate redundant engineering.

- Module reuse across many customer solutions, reducing complexity setup times and costs.

- Automated configuration tools that replace manual BOM generation.

Table 1 compares ETO and CTO across key cost-related operational areas, demonstrating how CTO outperforms ETO by driving cost efficiencies in Design Engineering, Testing & Verification, Procurement, Inventory, and Manufacturing, ultimately leading to higher profitability and cost leadership.

Table 1: Business Impact Comparison – ETO vs. CTO

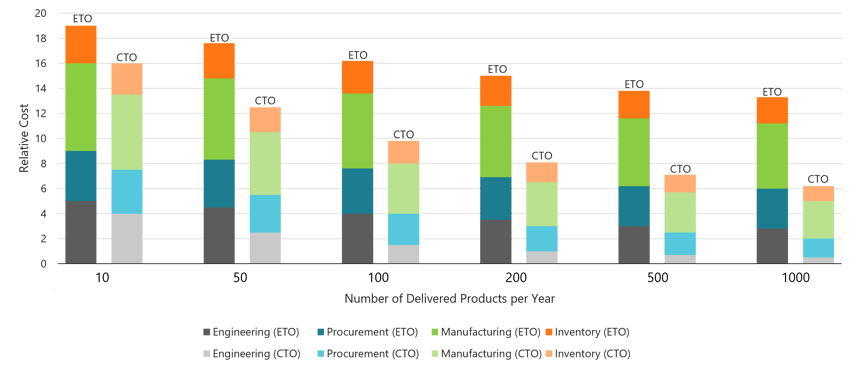

Figure 1 illustrates the relative cost reductions achieved by moving from ETO to CTO across key operational cost areas as the number of products delivered increases. By strategizing component re-use, reusing pre-validated modules, and streamlining manufacturing setups, HVAC manufacturers reduce costs by 50% in Design Engineering, 40% in Testing & Verification, 30% in Procurement, 40% in Inventory, and 25% in Manufacturing.

Figure 1: Cost Efficiency Gains by Transitioning from ETO to CTO.

Key Takeaway: Transitioning from ETO to CTO isn’t just about reducing costs—it’s about creating a scalable, high-efficiency product architecture that eliminates complexity at its source. By structuring products around common, reusable modules, HVAC manufacturers can expand variety without increasing operational burden, enabling long-term profitability and agility.

Trane Case Study: Achieves Increased Profitability Through Enhanced Configurability to Support CTO

Trane developed a new air handler product line based upon a strategic modular product architecture using the MFD methodology. The two previous product lines replaced were based upon decades of Engineer to Order efforts to meet new customer needs. They had also put much effort into automating the generation of production BOMs with the use of a rules based configurator, but the derivative design was not inherently configurable leading to constant maintenance, tying up high value engineering resources. In addition, the complexity drove excess cost and lead time issues in procurement and production. The new architecture greatly improved the configurability and the reuse of components by using pre-engineered modules that could be mixed and matched based upon customer needs.

With this CTO approach, Trane:

- Standardized core components, eliminating redundant engineering work.

- Simplified configuration rules, enabling sales teams to generate accurate orders aligned with manufacturing strategies and clean BOMs without requiring engineering revision of the configurator or design.

- Optimized procurement, reducing sourcing complexity with a product line that needed less than half the number of unique part numbers but could deliver a much wider range of solutions.

- Streamlined manufacturing, by consolidating two unique platforms into a common architecture that was much easier to build and and manage within the plant.

Figure 2: Trane Performance Climate Changer Air Handlers. The new, rearchitected family of air handlers that maximized configurability and reduced complexity.

The Results: Faster, More Profitable Growth

Trane achieved:

-

58% reduction in part numbers, simplifying procurement and reducing supply chain risk.

-

Greater than 35% increase in available footprints.

-

Significantly shorter lead times, as configured products could be delivered faster.

This program enabled Trane to scale its air handler business while maintaining customer flexibility—without the cost penalties of custom engineering.

Conclusion: Why CTO is the Future for HVAC Manufacturers

ETO models continuously add complexity, increasing costs and reducing efficiency. Shifting to CTO with strategic modular product architecture enables HVAC manufacturers to cut costs, streamline operations, and improve responsiveness without sacrificing customization.

With CTO, manufacturers can:

- Reduce engineering workload & design costs by using pre-validated modules instead of custom designs for every order.

- Cut testing & compliance costs by leveraging pre-certified modules, eliminating redundant verification cycles.

- Lower manufacturing costs through common production setups and batch production, improving efficiency.

- Optimize procurement & inventory by consolidating components across product lines, reducing SKUs and supplier complexity.

- Speed up time-to-market by enabling fast, flexible configuration, ensuring customers get the solutions they need—without long lead times.

Next Steps

If you’re still engineering every HVAC order from scratch, you’re not just slowing things down—you’re scaling complexity, not your business.

The transition from Engineer-to-Order (ETO) to Configure-to-Order (CTO) is more than a cost-saving tactic. It’s a transformation strategy for HVAC manufacturers who want to grow faster, simplify operations, and boost margins—without sacrificing product flexibility.

We’ve put together a focused set of resources to help you get started:

- Guide: The HVAC Manufacturer’s Guide to Transitioning from ETO to CTO – See what’s really driving cost inefficiencies and how to fix them.

- Self-Assessment Tool – Uncover where your product architecture may be holding you back from operating at scale.

- Modular Product Architecture Roadmap – A step-by-step guide to building a product platform that enables profitable growth.

Don’t let complexity erode your margins any longer. Download the full toolkit and take the first step toward a smarter, faster, more scalable business model.

Want to Know More?

If you’re interested in learning more about how we can support your business, feel free to get in touch.

Hank Marcy

Chief Account Executive

+1(09) 52 254 7608

hank.marcy@modularmanagement.com

LinkedIn

References

Modular Management. Market-Leading Position with Modular Design: Trane Technologies.